Having a common inspection platform for commoninspection needs in areas such as safety, performance and environmentalreliability upon electrical & electronic products, electronic equipment andpower secondary equipment. Standardized testing services can be conducted toensure that the quality of equipment developed and produced meets standard ortechnical specification requirements.

Service contents

• Qi certification test

• Environmental test

• Life test

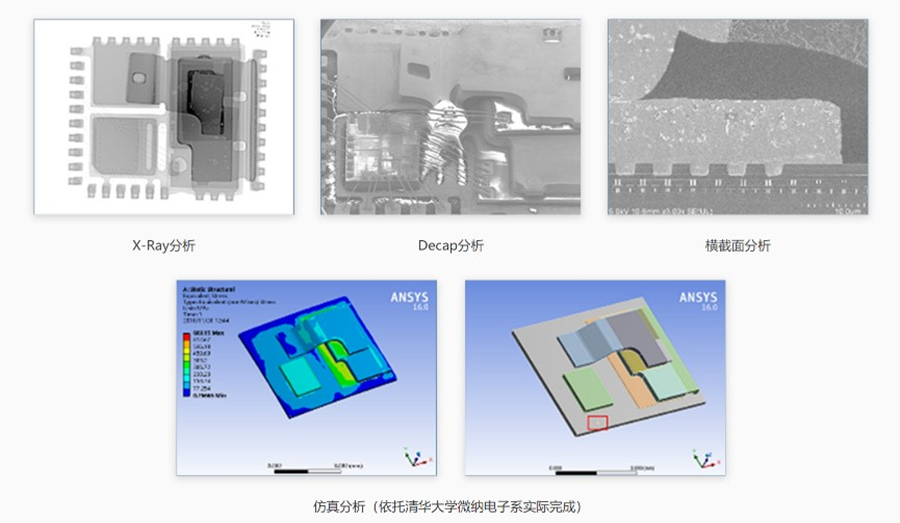

• Physical failure analysis

• Chemical failure analysis

• Electronical failure analysis

• Safety and performance test

• Digital operation and maintenance platform

• Dynamic simulation

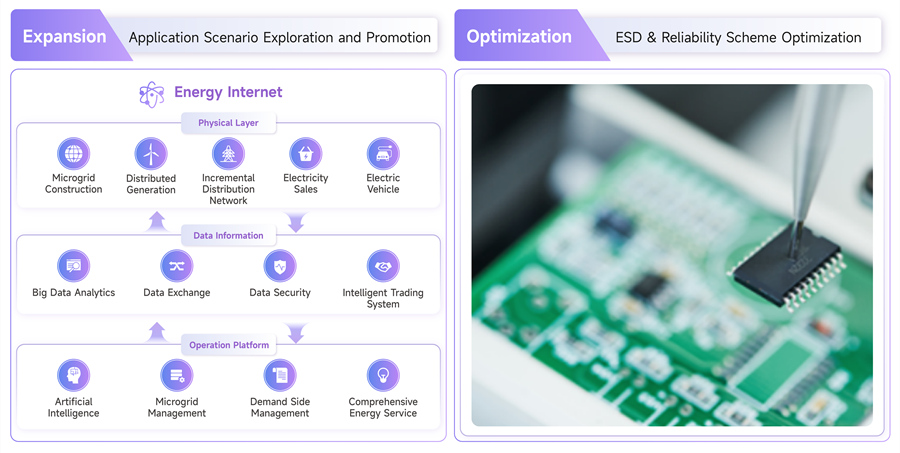

Technical service structure

1.Wireless charging products reliability

• Qi certification test

• Qi certification technical solution

• Wireless power transmission in-loop simulation

• Wireless power transmission efficiency

2.Reliability design and improvement

•Modeling, allocation and prediction

• FMECA、FTA、FRACAS• Test design and assessment

• Testability and maintanability engineering design

3.Reliability test and analysis

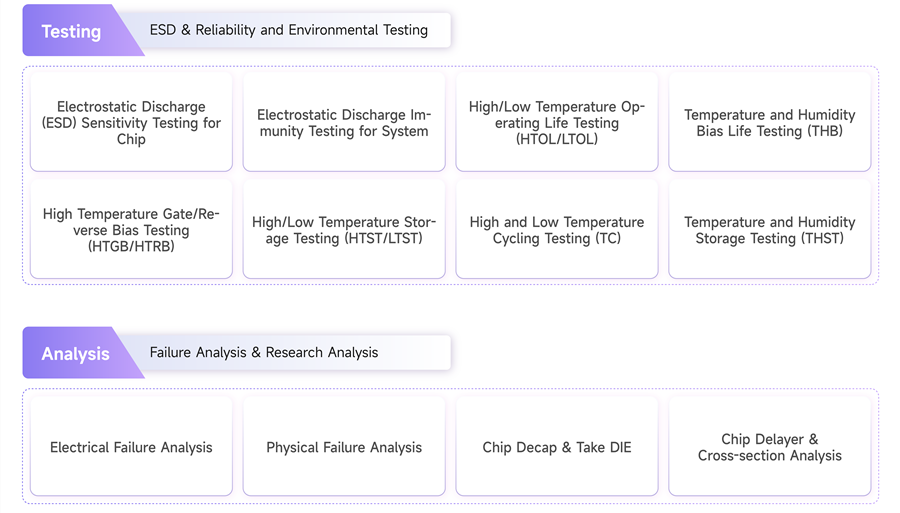

• Reliability test and analysis

• Safety test and optimization

• Fault and failure analysis

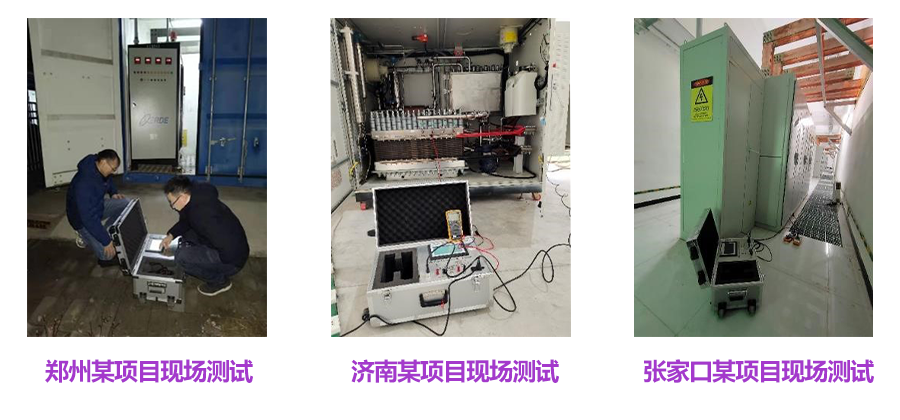

• Energy equipment dynamic simulation experiment

4.Prognostics and health management

• Fault mode and failure mechanism

• Fault diagnosis design

• Fault prediction design

• Prediction and health management system

Test Laboratory