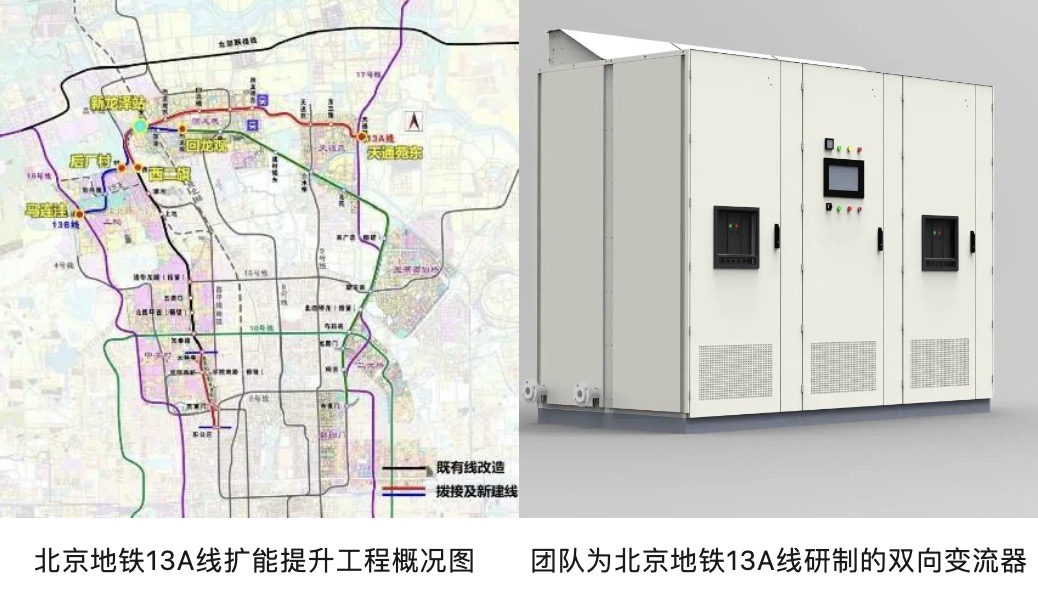

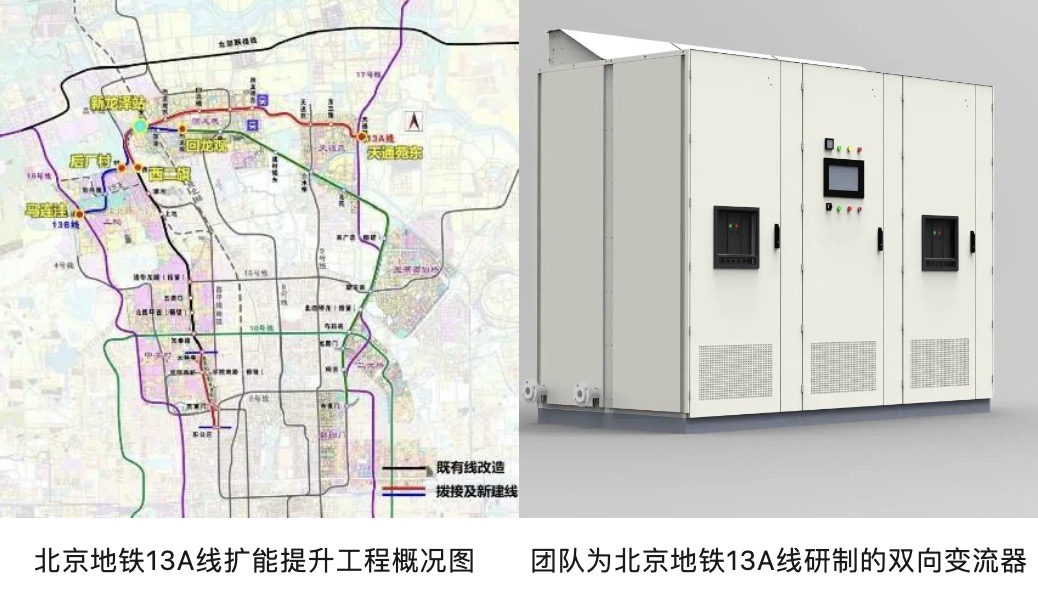

· Jointly undertake the project of Beijing Municipal Science & Technology Commission with Beijing Infrastructure Investment Co., Ltd., i.e. "Research on Key Technologies and Demonstration Application of Flexible DC traction Power Supply System for Urban Rail Transit". Beijing Metro Line 13A will become domestically the first urban rail flexible DC traction power supply system project with multiple cooperative control capabilities

· Jointly conduct the flexible DC traction power supply demonstration project for the first section of the railway from Tianjin central districts to Jinghai District with Tianjin Rail Transit and other institutions. The project has been successfully applied for the demonstration project of China Association of Metros. After put into operation, it will become domestically the first urban rail traction power supply system project directly adopting photovoltaic power for traction load power supply