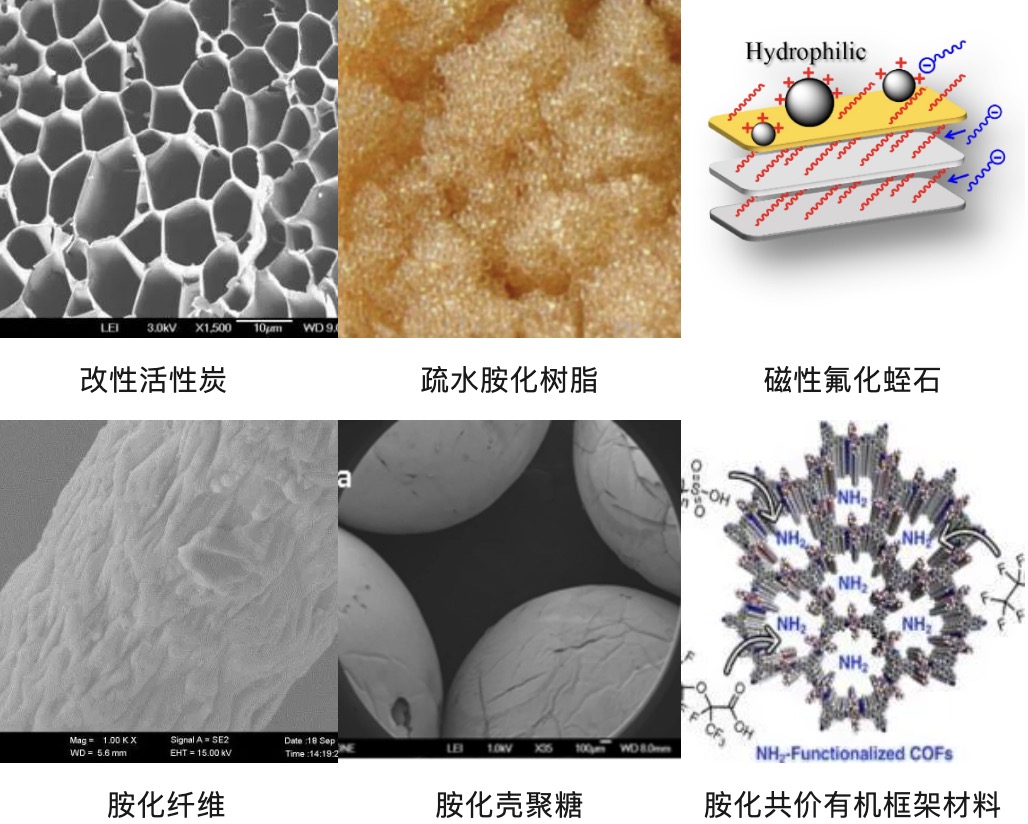

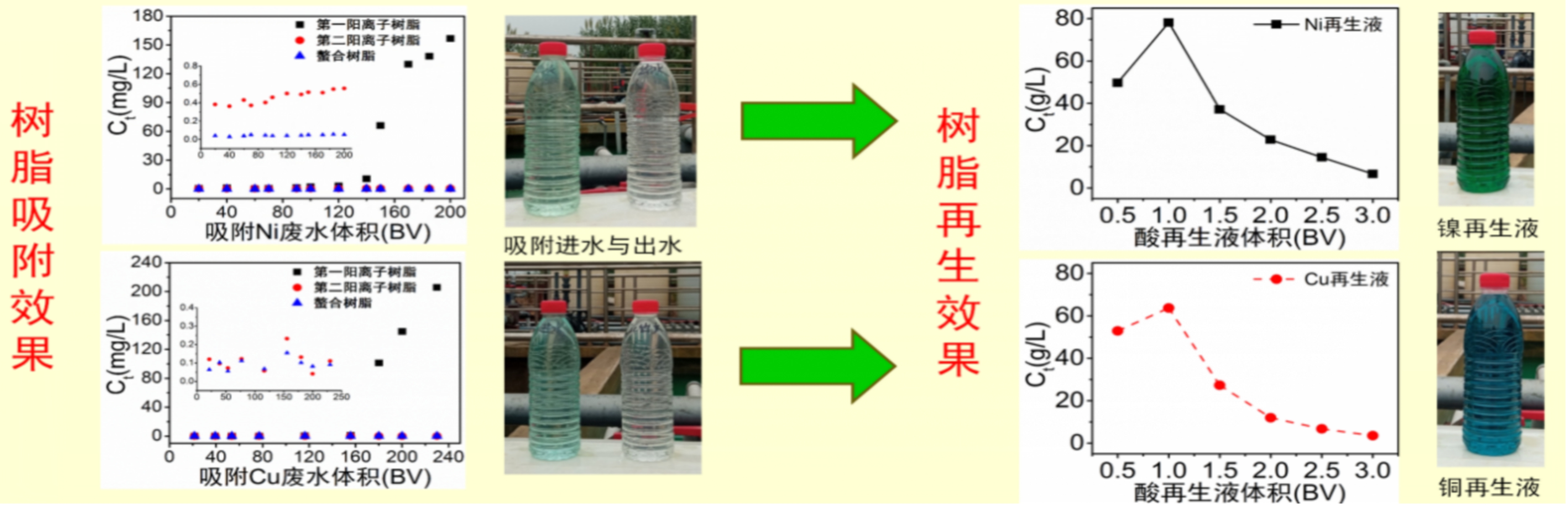

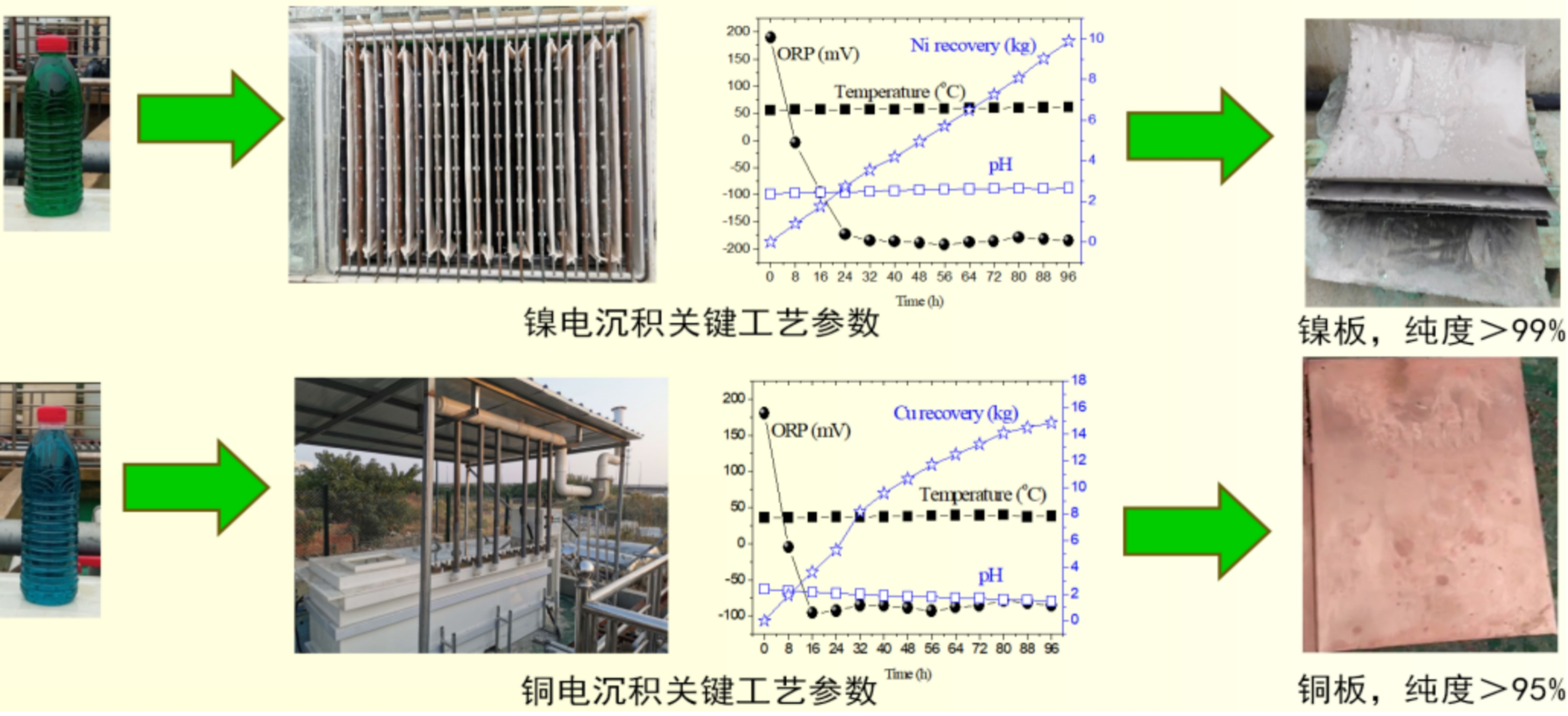

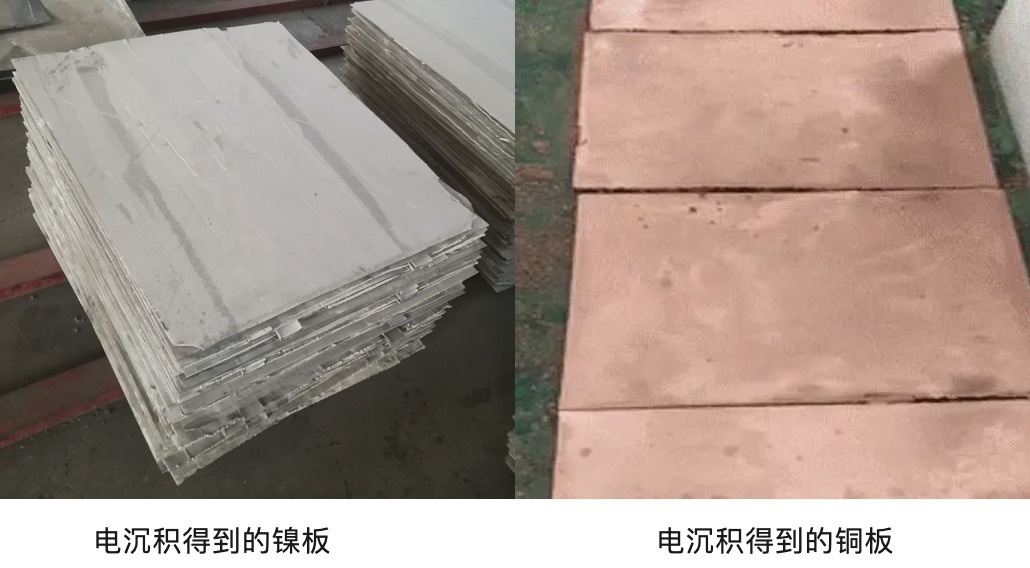

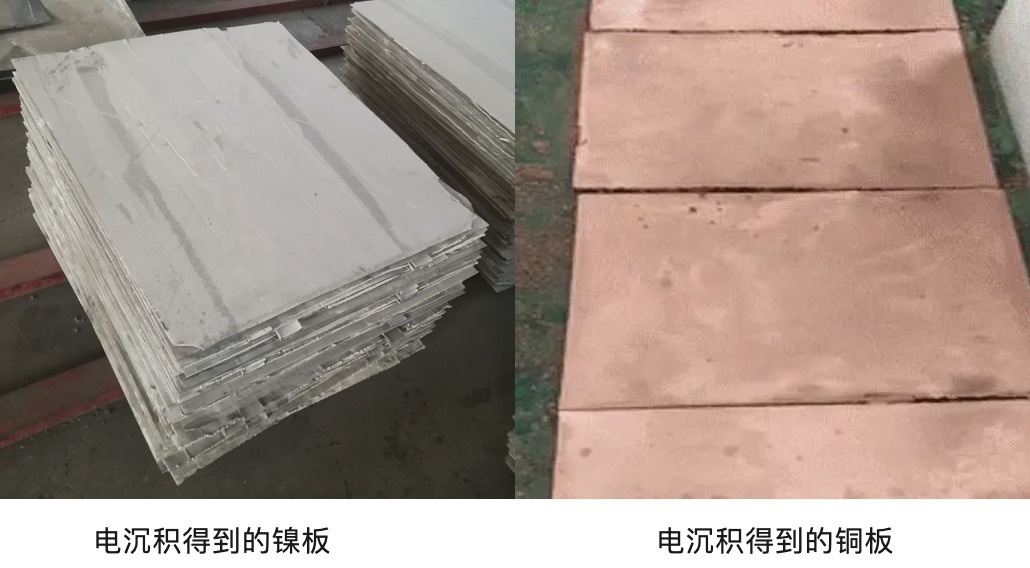

The key technological process combining resin adsorption and electrochemical deposition is developed targeting on the valuable nickel and copper in electroplating wastewater containing these elements. The technology is applied in the nickel and copper-containing wastewater treatment process in an electroplating industry in Changzhou, on a project scale of 120 tons per day. The recovery rate of nickel and copper is over 90% from wastewater, achieving both environmental and economical benefits. The heavy metal recovery technology combining resin adsorption and electrochemical deposition in this demonstration project has the advantage of low operating cost and high purity of products, as well as gaining positive profits from wastewater treatment, which can be promoted to the wider application in wastewater recycling project of electroplating parks across the country.

Figure: A demonstration set-up for recovery of heavy metals recovery from electroplating wastewater using resin adsorption-electrodeposition technology, as well as the obtained nickel & copper plates